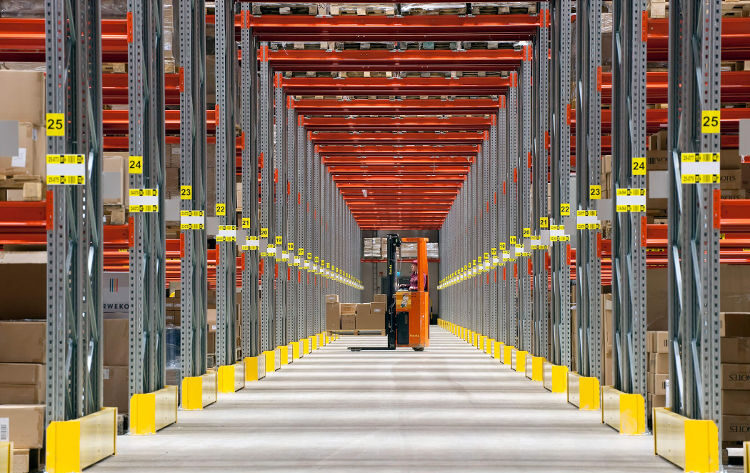

Knowing the needs of your warehouse and your company will allow you to create an ideal pallet racking system for your storage needs. These systems are versatile enough to use a combination of systems within the same warehouse and allow for use across a number of different industries. Pallet racks can be combined with other warehouse systems such as conveyors to create optimal product storage, handling, and shipment, saving time and money throughout a facility.

Once your storage rack is installed you might want to consider any number of warehouse safety considerations & accessories, such as pallet rack safety enclosures that help keep goods safely contained within the bays, rack labels which display the beam and rack capacities, and wire decking that allows you to store non-rack supported pallets of goods in a safe and stable manner.

To make the most out of a pallet rack system, it is essential to include all of the proper accessories and safety equipment. Also, inspection and repair of any damaged pallet racks are crucial to ensure proper warehouse safety.